StrongForce Redesigns DHL Warehouse with Hybrid Post-Tensioning and Precast Concept – Penang, Malaysia

February, 2023

StrongForce has recently completed the redesign of the DHL warehouse in Penang, Malaysia. Originally designed as a cast in-situ structure, the warehouse required a complex formwork system to accommodate the 18-metre-high levels. StrongForce was called upon to provide an alternative design solution that would simplify the construction method and accelerate the site program.

StrongForce has recently completed the redesign of the DHL warehouse in Penang, Malaysia. Originally designed as a cast in-situ structure, the warehouse required a complex formwork system to accommodate the 18-metre-high levels. StrongForce was called upon to provide an alternative design solution that would simplify the construction method and accelerate the site program.

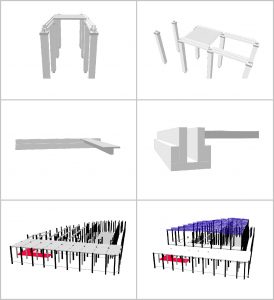

Working off a 12.0m x 12.5m column grid and an imposed live load of 40kPa, StrongForce converted the 3-level structure from a two-way band beam design to a hybrid post-tensioning and precast concept. Using the Rudloff-StrongForce multistrand system, the 186 shell beams and 1,186 T-Slab precast elements are being post-tensioned offsite and delivered to the warehouse.

The shell beams are erected onto the pile caps (L1) and onto the column corbels (L3) using post-tensioning within the shell. They’re then infilled, making the beams a solid rectangular continuous beam. The concept reduces the precast beam weight while providing continuity for the beam frame system, allowing for a reduction in the beam’s structural depth. The T-Slab precast is then placed on the adjacent shell beams with a structural topping.

This hybrid post-tensioning and precast concept is a welcomed solution for developers and project stakeholders constructing industrial buildings, as it accommodates large loading requirements while simplifying the construction method by eliminating the requirement for a temporary formwork system.

With StrongForce’s expertise and innovative solutions, the DHL warehouse in Penang, Malaysia now boasts a more efficient and cost-effective structural system, showcasing the company’s commitment to delivering quality engineering and construction solutions.

Afoul bridge to open Q1 2024 to ease traffic flow in Salalah region